|

상세 정보 |

|||

| 기술: | 초여과 장치 | 디자인: | 미끄럼 탑재 |

|---|---|---|---|

| 흐름 / TPD를 침투하세요: | 5~100/skid | 회복율: | 90~98% |

| TDS에게 / ppm을 공급하세요: | <35> | 물 임시.: | 5~35˚C |

| PH: | 2~11 | TSS/mg/L: | <100> |

| 혼탁도: | <300> | 자유 염소 mg/L: | 0 |

| 용해 철 mg/L: | <0> | 보증: | 1년이요 |

| 미끄럼 재료: | SS304/SS316L,carbon 강철 | 전압: | 380V,415V,220V, 맞춤화될 수 있습니다 |

| 애플리케이션: | 물 정화 동작, 정수기, 제약의, 식수, 식량 | 사이즈: | Depends,1750*550*1650mm |

| 기능: | 물 정화, 수신 전용 예비 처리 | 염분제거 비율: | 99%,99.7% |

| 제어: | 전자적, 설명서 / PLC | UF 막: | / 중국이 만든 하이드러노틱스 또는 다우지수 |

| 펌프: | CNP / 그룬트포스, CNP | ||

| 하이 라이트: | 9000TPD 산업적 초여과 체계,UF 산업적 한외여과 systems,9000TPD UF 수신 전용 시스템 |

||

제품 설명

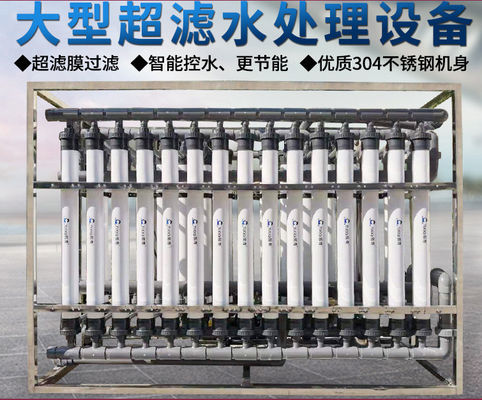

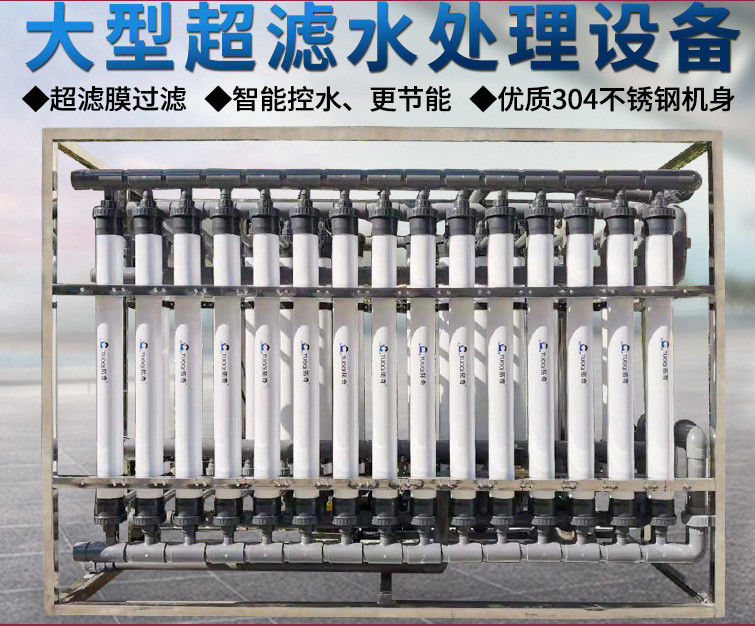

물 전처리를 위한 9000TPD 산업적 초여과 체계

Industrial ultrafiltration system for water pretreatment on SFP/D-2860 240TPD~9,000TPD skid mount

Ultrafiltration (UF) membranes systems are more reliable than a conventional multi-media filter, which removed approximately 10 micron or larger of matter, where an ultrafiltration membrane pore size ranges from 0.01 to 0.10 micron. In addition to superior turbidity removal, UF membranes efficiently remove bacteria and most viruses.

- Suitable as standalone system or pre-treatment for SWRO and BWRO systems

- Feed TDS for SUF system desigh ranges from 200~45,000 mg/L

- Permeate Turbidity < 0.2 NTU

- Energy consumption of SUF series is 0.2 to 0.4 kWh/m3

- Superior filtration performance with high flux

- Very small nominal pore diameter (0.03 µm)

- Efficiently removes bacteria and viruses

- Occasionally back washed and air scoured to boost performance and removing the fouling layer to extend operating life

- Low fouling membrane modules

- UF Outside-In or Inside-Out Configuration permits reduced plugging and higher solids loading

- Basic, vertical, modular design permits low cost, compact systems

- Effective membrane cleaning has a high chemical resistance and temperature tolerance

- VFD operated Feed / CIP pump

- VFD operated Backwash pump

- Automatic valves

- Complete set of piping

- Measurements and analysers

- RIO Panel (optional)

- Motor Control Centre (MCC) and Control Panel (CP)

| Feed Water Parameters | Units | Normal | Maximum |

| Turbidity | NTU | < 10 | < 25 |

| TSS | mg/L | < 20 | < 50 |

| TOC | mg/L | < 5 | < 15 |

| COD | mg/L | < 15 | < 30 |

| Total Oil & Grease | mg/L | Negligible | < 1 |

| Total Iron | mg/L | < 0.2 | |

| Total Manganese | mg/L | < 0.05 | |

| Total Colour | Pt-Co/L | < 10 | < 20 |

| Total Hardness as CaCO3 | mg/L | < 2,000 | < 3,000 |

| Product Water Parameters | Units | Expected Value | |

| Turbidity | NTU | < 0.2 | |

| SDI | - | < 3 | |

SUF system ranges

| Net Permeate Capacity |

Flow Rate | No.of UF Membranes |

Feed | Permeate | Concentrate | Dry Weight |

Wet Weight |

Dimension LxWxH | |||

| Model | (m3/d) | (m3/h) | (m3/d) | (m3/h) | Installation Connections (inch) | (kg) | (kg) | (m) | |||

| SUF-32 | 240 | 10 | 267 | 11 | 5 | 2” | 2” | 3” | 2,000 | 4,000 | 3.8 x 2.1 x 3.3 |

| SUF-50 | 360 | 15 | 400 | 17 | 8 | 2” | 2” | 4” | 2,500 | 6,000 | 4.4 x 2.5 x 3.3 |

| SUF-80 | 720 | 30 | 800 | 33 | 14 | 3” | 3” | 6” | 4,500 | 10,000 | 5.2 x 3.2 x 3.3 |

| SUF-100 | 1,440 | 60 | 1,600 | 67 | 26 | 3” | 3” | 6” | 5,500 | 15,000 | 7.1 x 3.5 x 3.6 |

| SUF-150 | 3,000 | 125 | 3,333 | 139 | 54 | 10” | 6” | 8” | 15,000 | 24,000 | 12.0 x 13.0 x 4.5 |

| SUF-200 | 4,800 | 200 | 5,333 | 222 | 86 | 14” | 8” | 8” | 21,000 | 31,000 | 15.5 x 17.0 x 4.5 |

| SUF-250 | 7,200 | 300 | 8,000 | 333 | 130 | 18” | 10” | 10” | 32,000 | 54,000 | 17.5 x 19.0 x 5.0 |

| SUF-300 | 9,000 | 375 | 10,000 | 417 | 160 | 20” | 12” | 10” | 35,000 | 59,000 | 17.5 x 19.0 x 5.5 |

| Model | SUF-32 | SUF-50 | SUF-80 | SUF-100 | SUF-150 | SUF-200 | SUF-250 | SUF-300 | |

| Permeate capacity (Max.) | m3/day | 240 | 360 | 720 | 1,440 | 3,000 | 4,800 | 7,200 | 9,000 |

| Concentrate rate (Min.) | m3/day | 27 | 40 | 80 | 160 | 333 | 533 | 800 | 1,000 |

| Feed rate (Max.) | m3day | 267 | 400 | 800 | 1,600 | 3,333 | 5,333 | 8,000 | 10,000 |

| System recovery (Max.) | % | 90 | |||||||

| Operating Temperature Range | °C | 20 - 35 | |||||||

| UF Feed Pump / UF CIP Pump / UF Backwash Pump | |||||||||

| Model | CHL or NBG or equivalent | ||||||||

| Manufacturer | CNP or Grundfos or equivalent | ||||||||

| Quantity | 1 | ||||||||

| Motor (Feed Pump) | kW/HP | 3 / 4 | 4 / 5.5 | 7.5 / 10 | 7.5 / 10 | 22 / 30 | 37 / 50 | 55 / 75 | 75 / 100 |

| Motor (CIP Pump) | kW/HP | 15 / 20 | 30 / 40 | 45 / 60 | 45 / 60 | ||||

| Motor (Backwash Pump) | kW/HP | 2.2 / 3 | 4 / 5 | 7.5 / 10 | 18.5 / 25 | 30 / 40 | 45 / 60 | 75 / 100 | 75 / 100 |

| Operation | VFD Operated | ||||||||

| MOC | Seawater: Duplex Stainless Steel, Brackish Water: SS316 | ||||||||

| Membrane Elements and Housings | |||||||||

| Membrane Model | SFX-2860 or equivalent | ||||||||

| Membrane Manufacturer | DOW or other equivalent | ||||||||

| Membrane Quantity | 5 | 8 | 14 | 26 | 54 | 86 | 130 | 160 | |

| Nominal Molecular Cut-off Weight |

Daltons | 100K | |||||||

| Housing Shell MOC | uPVC | ||||||||

| Flow Type | Outside-in | ||||||||

| Installation and Utility Requirements | |||||||||

| UF Feed flange end | 2” | 3” | 10” | 14” | 18” | 20” | |||

| UF Permeate flange end | 2” | 3” | 6” | 8” | 10” | 12” | |||

| UF Feed Water Pressure (min.) | bar | 0.2-2 | |||||||

| Air Pressure (oil free) | bar | 7 | |||||||

| Waste water volume for drain trench sizing requirement | MLD / m3/hr |

0.28 / 12 | 0.38 / 16 | 0.84 / 35 | 0.84 / 35 | 7.2 / 300 | 12 / 500 | 19.2 / 800 | 19.2 / 800 |

| Power | 400 VAC +/- 20%, 3-phase, 50/60Hz | ||||||||

| Control circuit | 120/220V, 1-phase, 50/60Hz | ||||||||

| Measuring Instruments | |||||||||

| Pressure switch | Instrument air line | Instrument air line, UF feed pump | |||||||

| Pressure guage | Instrument line, UF air scouring line, Reject recirculation line, UF permeate line | Instrument line, UF air scouring line, Reject recirculation line, UF permeate line, CIP pump discharge, Backwash pump discharge, NaoCl, HCl, NaOH pump discharge. | |||||||

| Flow indicator (rotameter) | UF air scouring line, Reject recirculation line | ||||||||

| Flow measurement | UF permeate line, Reject recirculation line | ||||||||

| Pressure transmitter | UF Feed | ||||||||

| Analyzers | Turbidity meter (Optional) | pH meter for UF CIP, Turbidity meter (optional) | |||||||

| Level Switch | UF feed / CIP tank, Backwash tank | NaOCl, HCl, NaoH Dosing tank | |||||||

| Level Transmitter | UF feed / CIP tank | UF CIP tank / Backwash tank | |||||||

| Recommended Tank Size | |||||||||

| UF Feed tank | m3 | 15 | 25 | 50 | 75 | 100 | 150 | 200 | 250 |

| UF Permeate tank* | 15 | 25 | 50 | 75 | 100 | 150 | 200 | 250 | |

| CIP tank | 0.55 | 0.9 | 1.8 | 2.7 | 8 | 12 | 20 | 22 | |

| Overall System Dimensions (based on above volumes) | |||||||||

| Dimensions (L x W x H) | m | 3.8 x 2.1 x 3.3 | 4.4 x 2.5 x 3.3 | 5.2 x 3.2 x 3.3 | 7.1 x 3.5 x 3.6 | 12 x 13 x 4.5 | 15.5 x 17 x 4.5 | 17.5 x 19 x 5 | 17.5 x 19 x 5.5 |

| Skid Configuration | Single Skid | UF feed pump & auto-strainer skid, UF valve rack skid, UF module skid, UF CIP pump skid, UF backwash skid, UF chemical dosing skid | |||||||

| Dry Weight (without membranes) |

kg | 2,000 | 2,500 | 4,500 | 5,500 | 15,000 | 21,000 | 32,000 | 35,000 |

| Wet Weight | kg | 4,000 | 6,000 | 10,000 | 15,000 | 24,000 | 31,000 | 54,000 | 59,000 |

![]()