|

상세 정보 |

|||

| 기술: | Pretreatment+Reverse 침투 / UF / NF 기타 등등. | 디자인: | 컨테이너이스드 미끄럼 탑재 / |

|---|---|---|---|

| 흐름 / TPD를 침투하세요: | 0.25~1000 | TDS에게 / ppm을 공급하세요: | <2> |

| 물 임시.: | 5~35˚C | PH: | 4~9 |

| TSS/mg/L: | <5> | 막 오염 지수: | <3> |

| Free chlorine mg/L: | 0 | 용해 철 mg/L: | <0> |

| 재료: | SS304/SS316L,carbon 강철 | 전압: | 380V,415V,220V, 맞춤화될 수 있습니다 |

| 애플리케이션: | 물 정화 동작, 정수기, 제약의, 식수, 식량 | 기능: | 물 정화, 정수기, 담수화 |

| 강조하다: | OEM 정제수 처리 시스템,모듈 정제수 처리 시스템,OEM 정수시설 |

||

제품 설명

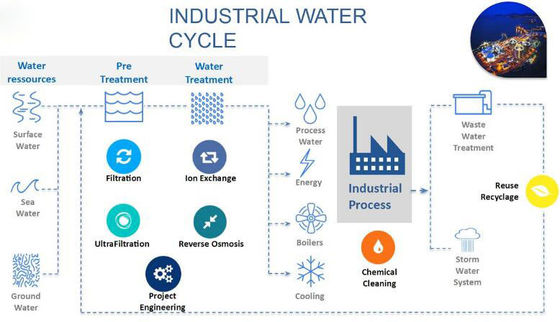

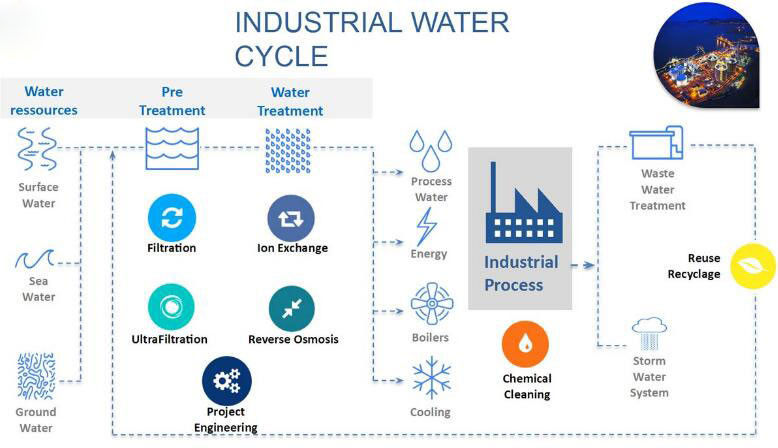

Technologies and water treatment processes for purification and recycle in industries

Our technologies and water treatment processes combine to provide industrial water treatment:

- Biological Processes

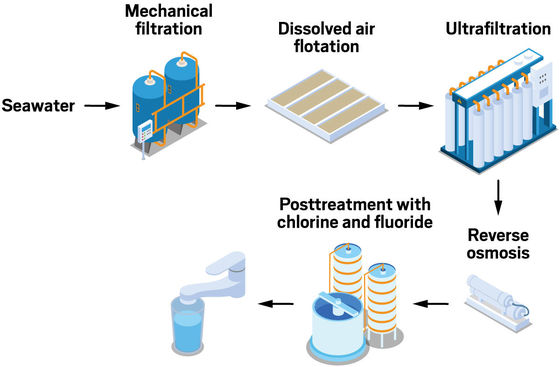

- Desalination

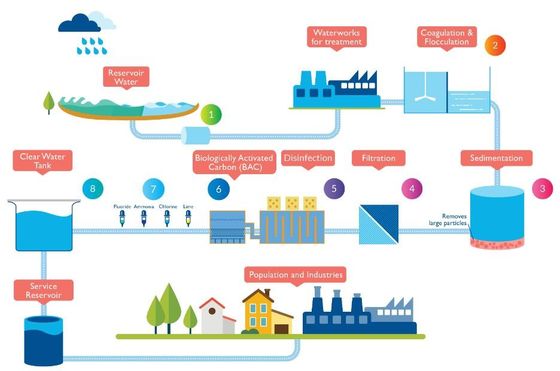

- Clarification

- Disinfection

- Filtration

- Ion Exchange

- Membrane Separation

- Package Plants

- Sludge Treatment & Handling

INDUSTRIAL WATER TREATMENT SOLUTIONS

Our industrial water treatment solutions are divided into 2 categories: Water Treatment Processes, Wastewater Treatment

Water Treatment Processes

Water treatment processes include water purification package plants, water purification technologies and reverse osmosis plants. These processes allow our customers to treat industrial water for both process and potable water to industry standards, and both local and international regulatory requirements.

Water purification package plants, also called modular plants or containerized plants, are easy to transport and designed for ‘plug-and-play’ action with minimal moving parts. Water purification technologies achieve highly purified water for specialized industrial use and for potable water; and reverse osmosis plants facilitate water recycling and reuse.

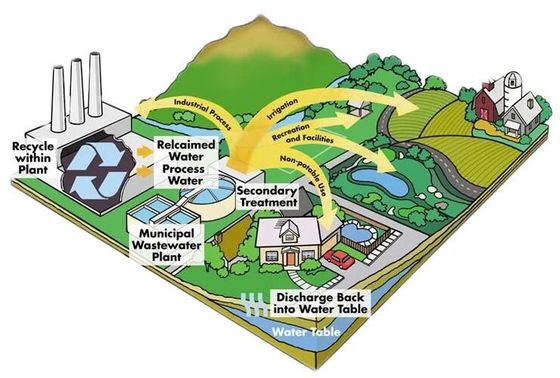

Wastewater Treatment

Wastewater treatment solutions incorporate industrial wastewater treatment; package plants for wastewater treatment; wastewater treatment chemicals and wastewater treatment technologies. Wastewater is treated to either process or potable water standards, with distinct benefits to both industry and municipalities.

Wastewater treatment technologies are tailored to meet the strictest disinfection and purification specifications; package plants for wastewater provide several economic benefits, are compact, reliable and easily transportable to remote locations; and industrial wastewater treatment provides solutions for specific industries.

Industrial RO Array Specifications

| Model | Vessel Array | Vessel Size | Vessel Quantity | Membrane Size | Membrane Quantity |

| HM – 4240 | 2:2 | 4080 | 4 | 4040 | 8 |

| HM – 6240 | 2:2:2 | 4080 | 6 | 4040 | 12 |

| HM – 8240 | 3:3:2 | 4080 | 8 | 4040 | 16 |

| HM – 10240 | 3:3:2:2 | 4080 | 10 | 4040 | 20 |

| HM – 12240 | 3:3:2:2:2 | 4080 | 12 | 4040 | 24 |

Product Specifications

| Models | HM – 4240 | HM – 6240 | HM – 8240 | HM – 10240 | HM – 12240 |

| Design | |||||

| Configuration | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass |

| Feedwater Source† | TDS <10,000 ppm | TDS <10,000 ppm | TDS <10,000 ppm | TDS <10,000 ppm | TDS <10,000 ppm |

| Standard Recovery Rate % | 40 – 50 | 40 – 50 | 40 – 50 | 30 – 45 | 46 – 52 |

| Rejection and Flow Rates††† | |||||

| Nominal Salt Rejection % | 99.2 | 99.2 | 99.2 | 99.2 | 99.2 |

| Permeate Flow* (gpm / lpm) | 8.30 / 31.41 | 12.50 / 47.31 | 16.70 / 63.21 | 20.80 / 78.74 | 25.00 / 94.63 |

| Minimum Feed Flow (gpm / lpm) | 14.30 / 54.13 | 18.50 / 70.03 | 22.70 / 85.93 | 26.80 / 101.45 | 31.00 / 117.35 |

| Maximum Feed Flow (gpm / lpm) | 28 / 106 | 28 / 106 | 42 / 159 | 42 / 159 | 42 / 159 |

| Minimum Concentrate Flow (gpm / lpm) | 6 / 23 | 6 / 23 | 6 / 23 | 6 / 23 | 6 / 23 |

| Connections | |||||

| Feed FNPT (in) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Permeate FNPT (in) | 1 | 1 | 1 | 1.5 | 1.5 |

| Concentrate FNPT (in) | 1 | 1 | 1 | 1.5 | 1.5 |

| CIP FNPT (in) | 1 | 1 | 1 | 1 | 1 |

| Membranes | |||||

| Membrane(s) Per Vessel | 2 | 2 | 2 | 2 | 2 |

| Membrane Quantity | 8 | 12 | 16 | 20 | 24 |

| Membrane Size | 4040 | 4040 | 4040 | 4040 | 4040 |

| Vessels | |||||

| Vessel Array | 2:2 | 2:2:2 | 3:3:2 | 3:3:2:2 | 3:3:2:2:2 |

| Vessel Quantity | 4 | 6 | 8 | 10 | 12 |

| Pumps | |||||

| Pump Type | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage |

| Motor HP | 7.5 | 7.5 | 10 | 10 | 15 |

| RPM @ 60 Hz | 3450 | 3450 | 3450 | 3450 | 3450 |

| RPM @ 50 Hz | VFD at 60Hz | VFD at 60Hz | VFD at 60Hz | VFD at 60Hz | VFD at 60Hz |

| System Electrical | |||||

| Standard Voltage + Amp Draw | 220V, 60Hz, 3PH, 19.5A** | 220V, 60Hz, 3PH, 19A** | 220V, 60Hz, 3PH, 26.6A** | 220V, 60Hz, 3Ph, 26.6A** | 220V, 60Hz, 3Ph, 36A** |

| High Voltage Service + Amp Draw | 220V, 50Hz, 3PH, 22.9A** 460V, 60Hz, 3PH, 9.7A** |

220V, 50Hz, 3PH, 22.9A** 460V, 60Hz, 3PH, 9.7A** |

220V, 50Hz, 3PH, 30.9A** 460V, 60Hz, 3PH, 12.9A** |

220V, 50Hz, 3PH, 30.9A** 460V, 60Hz, 3PH, 12.9A** |

220V, 50Hz, 3PH, 45A** 460V, 60Hz, 3PH, 18.5A** |

| Systems Dimensions | |||||

| Approximate Dimensions* L x W x H (in / cm) | 31 x 100 x 64 / 787.4 x 2540 x 1626 |

31 x 100 x 64 / 787.4 x 2540 x 1626 |

31 x 100 x 64 / 787.4 x 2540 x 1626 |

31 x 100 x 64 / 787.4 x 2540 x 1626 |

31 x 100 x 64 / 787.4 x 2540 x 1626 |

| Weight lb. (kg) | 1260 / 572 | 1350 / 611 | 1460 / 662 | 1550 / 703 | 1650 / 748 |

Test Parameters: 10,000 TDS Filtered (5 –Micron), Dechlorinated, Municipal Feedwater, 65 psi / 4.50 bar Feed Pressure, 350 psi / 24.13 bar Operating Pressure, 77ªF / 25ªC, Recovery as stated, 7.0 pH. Data taken after 60 minutes of operation.

* Does not include operating space requirements.

** Varies with motor manufacturer.

Markets

Industrial water treatment for markets is designed to aid companies produce process water according to industry standards, recycle plant water for reuse, discharge water that does not cause environmental damage and manage wastewater correctly. We provide tailored industrial water treatment solutions.

- Automotive plants: use reverse osmosis, ultrafiltration and microfiltration for high quality products

- Food and beverage: make use of multimedia and membrane filtration, activated carbon filtration and UV disinfection

- Mine water and wastewater: treats mine sludge, enables reuse of process water and extract valuable minerals from water streams

- Petrochemical: Designed specifically for the oil & gas upstream and downstream industries, key technologies for oil/water separation and sludge treatment are used

- Pharmaceutical: used to achieve highly purified water, pyrogen-free water and water for injection

- Power Plant: ideal for boiler feed water, cooling water production, water chemical condition, effluent treatment and water reuse

- Pulp and Paper: included in the range of treatments are black liquor, chloride and potassium removal technologies. Some processes recover fibre and more from waste streams

- Steel Processing: Technologies like clarification, crystallisation and membrane technology are used

![]()

![]()

![]()